Restoration of Maple Syrup Evaporator Combustion Fire Box |

| |

|

|

|

|

|

Sleepy Hollow Chimney was found in 1978 in response to the last energy crisis. We are the oldest independently run chimney supply company in the U.S. We are acknowledged by our peers to have created benchmark wood heat related technologies that have withstood the test of time are the standard today.

1980 – Super Flex® Heavy Duty interlocked flexible flue lining system

1985 – Cera-Foil® High temperature ceramic fiber insulating blanket for flexible and rigid stainless flue liners

1989 - Bellfires® Refractory Fireplace the world’s premier open hearth clean burning, gasification wood burning fire boxes, unmatched as a retrofit safety renovation to any existing masonry fireplace (1780-1980), BCC wood floor units for new construction or the simple affordable addition of a new fireplace to your home.

High Temperature Stainless Steel Metal Fabrication

Our sheet metal work is renowned coast to coast. Let us help your maple sugar evaporation adventure in the following ways:

Repair rebuild or new flue and syrup pans.

Stainless Steel sap pails

Stainless Steel Flue transitions

Stainless Steel flue pipe sections – 22ga / 24ga and 304-L / 316-L

Stainless Steel Steam hoods and piping

Stainless Steel Tee’s and elbows

Spider Top Sealing Stainless Dampers

Custom Rain Caps

High Temperature Ceramic Fiber Blanket, available in ¼”, ½”, 1”, 2”, 3”, 4” thickness

Ceramic Fiber Insulating Boards, available in ½”, 1”, 2” thickness

Super Cement Hi Temp Mortar premixed

Super Mix Castable light weight insulation

Perlite – Pourable loose fill insulation

Ceramic and Fiber Glass Gasketing

Insulated Double Wall Metalbest

|

|

Today there is a performance gap that is limiting best results of your maple syrup evaporation effort. We can help you identify and upgrade evaporator problems.

Below are areas of improvement:

Many evaporators burn too much wood and waste heat up the flue. Three principles must be adhered to as best as possible

- Time

- Temperature

- Turbulence

Time – is the duration your combustion process can linger in the evaporators

Temperature – The higher the firebox area that combustion takes place, the cleaner the burn, 1200 F is a temperature that will burn the various combustible gases that heating up wood emits.

Better air control into the firebox and the placement of advanced ceramic fiber and High Alumina Refractories can easily achieve this.

Turbulence – is the mixing of air and gas molecules, the bouncing around movement that is improved by paying attention to and adding baffling.

Keeping the three T’s in mind as you operate your evaporator is important to fuel/evaporation proportion. It all happens in the fire box, when you can view photos on the internet, showing flames emitting out of the top of the exhaust flue. Too much wood energy is wasted. Many evaporators are too big of a flue, more negative pressure equals too much heat loss, if the external skin temperatures of your evaporator skin is glowing red or too hot to stand near this can be corrected.

In stock 70% alumina precast refractory fire box replacement panels loading cast iron doors and ash doors.

Stainless Ash Pan Fabrication.

Bellfires® Hand Forged Ash Rakes.

High Temperature Stove Gloves.

Chimney Brushes and Rods (a clean flue is a safe flue). |

| |

| Restoration of Maple Syrup Evaporator |

|

|

| Stainless Steel Ash Pan |

Stainless Steel Ash Pan with Outside Air Intake (Ideal to add and Inline fan/Blower) |

|

|

| 70% Alumina Refractory Panel Gasification Firebox Upgrade |

Firebox Chamber with Modified Cast Iron Grate |

|

|

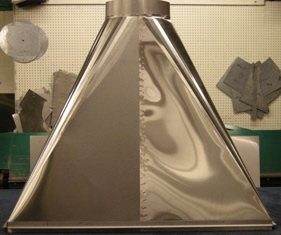

Stainless Steel Transition (Rectanguler to Round) |

Stainless Steel Steam Evaporation Hood (evaporates moisture and produces a higher temperature boil) |

| |

|

| To Complete Installation with Chimney |

|

|

| Stainless Steel Rigid Flue Pipe |

Double Wall Stainless Steel Metalbest pipe, Storm Collar, Flashing, Class A Enviro Rain Cap and Spider Damper (on top of the box) |

|

|

| Foil Face Ceramic insulation, Fiber Glass and Rope Gasketing and Ceramic Fiber Board |

|

| |

Call 1-800-553-5322 or Email your requirements.

|

| |

|

|

|

|

|

| |

|

|

|

|

|

| |

|

|

|

|

|